Ørsted continues to innovate in the offshore wind industry with the Borssele 1 & 2 wind farm

Located in the Dutch North Sea, the Borssele 1 & 2 offshore wind farm is an "open innovation lab" where offshore wind, technology, and innovation converge. The wind farm celebrated its fifth anniversary in August 2025 and comprises 94 wind turbines with a total capacity of 752 MW.

Smart Delta Resources partner Ørsted is responsible for the operations and maintenance of the wind farm. Ørsted's regional Operations and Maintenance team in the Vlissingen/Zeeland region was built from the ground up and has grown into an entrepreneurial team with a strong can-do attitude. This ensures reliable operations and enables Ørsted to test and scale new ideas offshore.

Borssele Wind Farm was the starting point for several firsts and pilots, including:

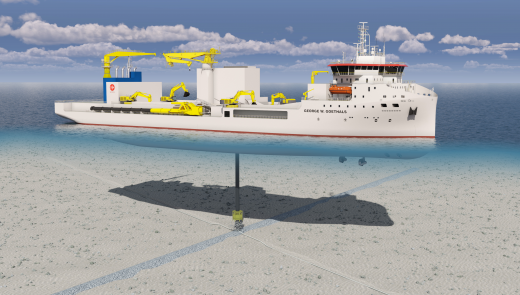

- The world’s first deployment of Heavy Lift Cargo Drones - to transport goods between a ship and the Borssele 1&2 wind turbines.

This was a world first for the offshore wind industry. The drones can deliver their cargo directly to the 94 turbines, making operational work more efficient and safer.

- Installation of oyster structures – contributing to the recovery of the native oyster population. Handy oyster structures can be easily installed by manually placing them on the seabed from the deck of a small vessel. This allows the structures to be transported and installed during regular maintenance activities at the wind farm. The method represents a significant improvement in ease of installation, cost-efficiency, and scalability.

- Artificial reefs for cod - a pilot project for nature-inclusive design to create habitats for important marine species.

- An AI-driven bird monitoring initiative - to advance data-driven biodiversity conservation.

Ørsted and Spoor have joined forces for a pilot project using AI technology to monitor bird behavior at the Borssele 1&2 offshore wind farm. Three advanced high-resolution cameras have been installed at two turbines in the wind farm to continuously monitor bird flight behavior during the day.

By investing in drone technology, innovative installation methods, and promoting biodiversity, Ørsted is making significant technological advancements in the offshore wind industry. This not only contributes to the energy transition but also to efficient operations and a commitment to the marine ecosystem.