Ørsted develops innovations within the offshore wind industry

For the first time, Ørsted has deployed Heavy Lift Cargo Drones (HLCD) to transport cargo between a ship and the Borssele 1&2 wind turbines. This is considered a world first for the offshore wind industry. The drones can deliver their cargo directly to the 94 turbines, making operational work more efficient and safer.

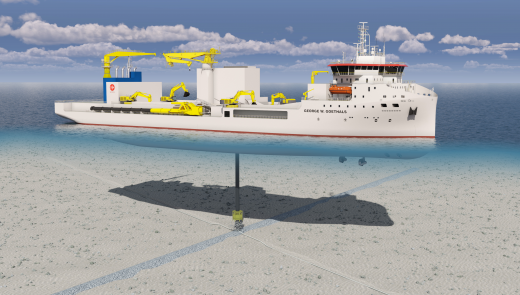

In addition, Ørsted has successfully tested a new technology for installing wind turbine foundations at the Gode Wind 3 wind farm in Germany. This new technology, which uses a patented jetting technique, reduces the resistance of the sandy soil, allowing the foundations to sink into the seabed without hammering. This innovation drastically reduces noise levels during installation. With a reduction of 34 dB compared to conventional methods, the technology offers a much quieter installation procedure with less impact on marine life.

By investing in both drone technology and innovative installation methods, Ørsted is making significant technological progress within the offshore wind industry. In this way, they not only contribute to the energy transition, but also to an efficient one and they take the marine ecosystem into account.

Read the full articles about these innovations on the Ørsted website:

Ørsted launches world’s first heavy-lift cargo drone operations at Borssele 1&2 Offshore Wind Farm

Ørsted successfully pilots new technology that further optimises offshore wind monopile installation